We have the capability to satisfy your umbilical, HFL and gas lift jumper needs. One of our more recent projects supplied a scope of 2 inch UH-500 series stab connectors with Steel Tube Flying Leads (STFL) for a client in the Gulf of Mexico.

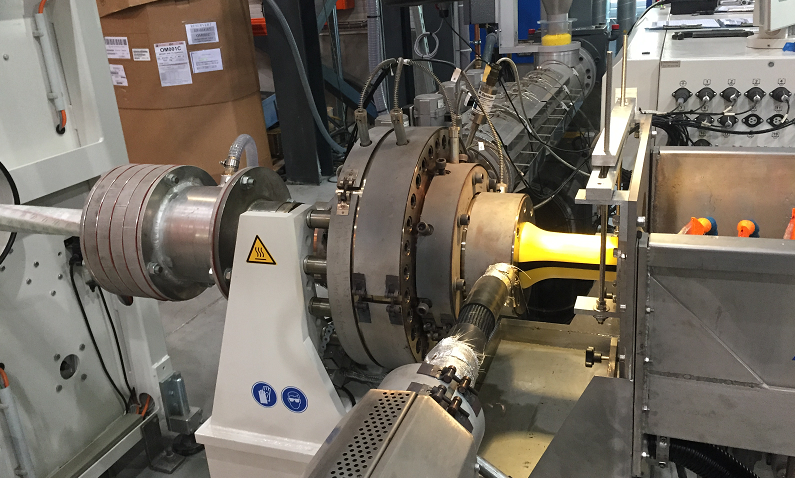

The bundling of the tubes incorporated a back twist to create a balanced construction. The bundle was taken through an extrusion system and spooled directly onto a reel.

Figure 1 – Extrusion machine

A reel was specifically made to suit the installation method to reduce project cost and interface time. In addition, the reel was made to be re-used on the next delivery after refurbishment.

Figure 2 – Reel prior to spooling of bundle

The manufacturing system is a vertical bundling and extrusion line with flexible configurations, up to 18 tubes with secondary pass possibility, and the ability to incorporate electrical and fiber components. A Siemens automated control system ensures accurate control and logging of speed, back twist and lay length.

Figure 3 – Bundle fully loaded onto reel

We have direct Deepwater shipping access from our Stord, Norway facility which improves project cost constraints by facilitating rapid delivery to project locations.

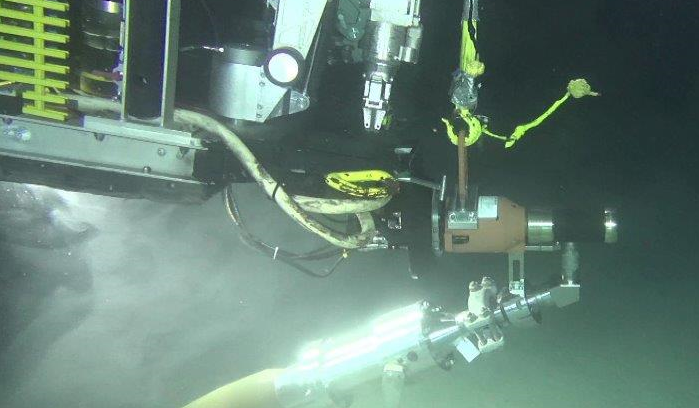

Figure 4 – ROV installation of bundle subsea

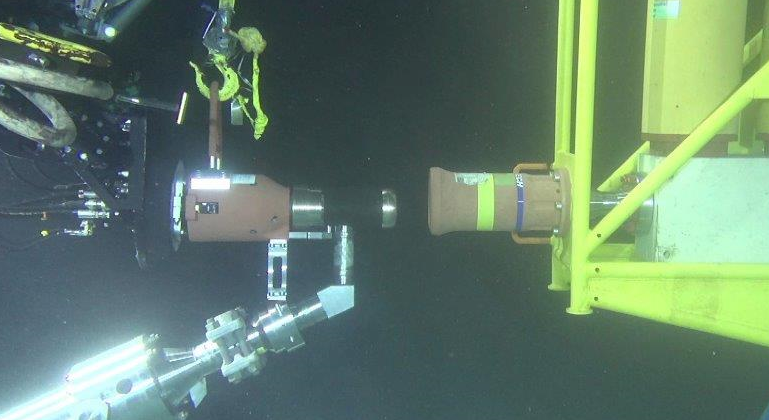

Figure 5 – ROV installation of bundle subsea

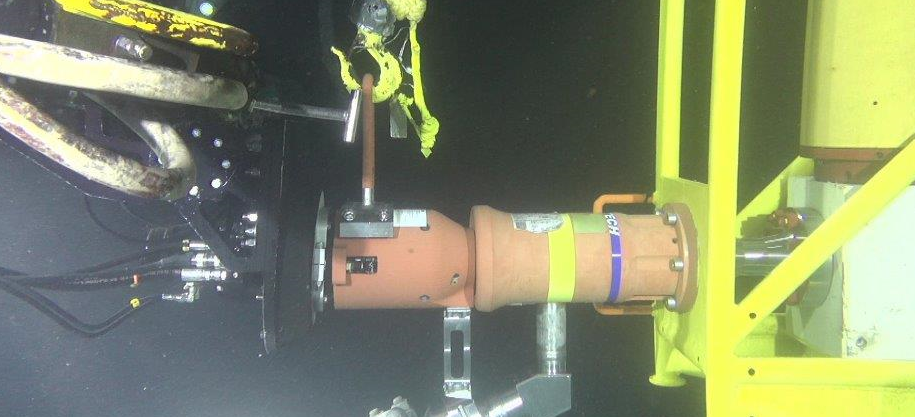

Figure 6 – ROV installation of bundle subsea

For more information contact sales@unitechsubsea.com.